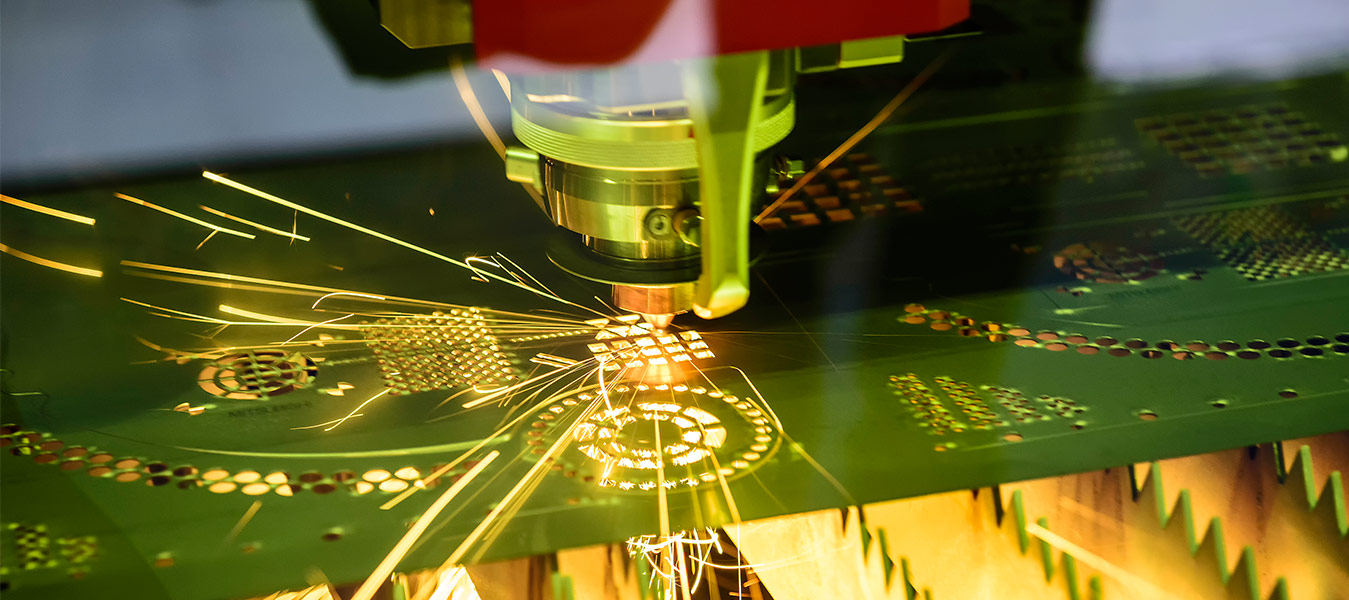

Project Design

Izmir Laser uses the most up-to-date versions of 3D design and technical drawing programs such as Cad-Cam, Solid Works and Auto Cad with its expert team. In addition to helping you develop new products and projects, it meticulously undertakes and fully fulfills the demands necessary for the production of highly developed products and projects.